国内首个食品冷链物流强制性国家标准来了

标准号:GB 31605-2020

发布日期:2020-09-11

实施日期:2021-03-11

1 范围

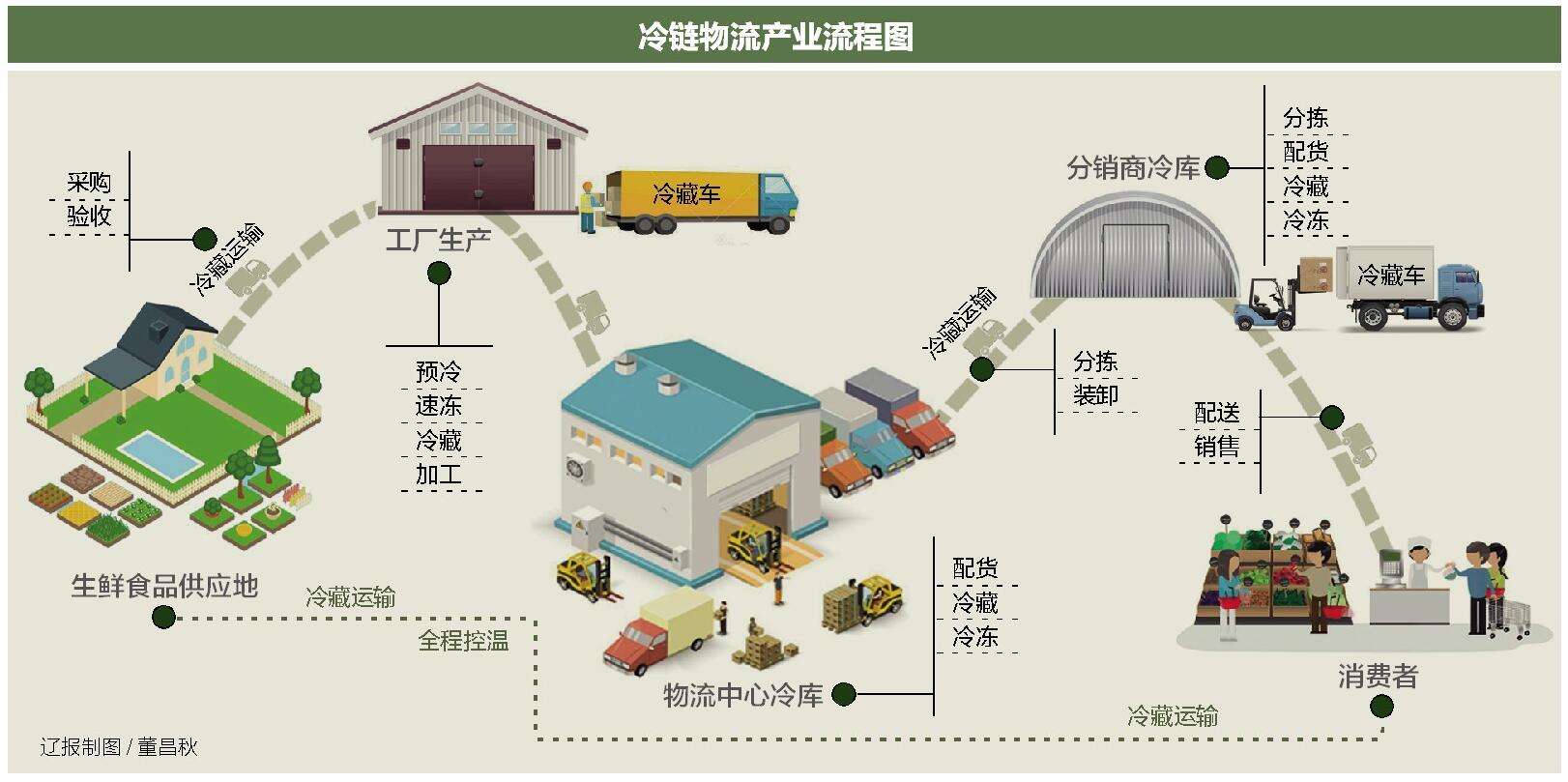

本标准规定了在食品冷链物流过程中的基本要求、交接、运输配送、储存、人员和管理制度、追溯及召回、文件管理等方面的要求和管理准则。

本标准适用于各类食品出厂后到销售前需要温度控制的物流过程。

2 术语和定义

2.1 食品冷链物流

以温度控制为主要手段,使食品从出厂后到销售前始终处于所需温湿度范围内的物流工程。

2.2 交接

冷链物流过程中的环节,包括入库交接、出库交接和配送交接等。

3 基本要求

3.1 应配备与冷链食品生产经营相衔接的冷库、运输工具或其他符合冷链食品储存温湿度要求的设施设备。冷库、运输工具等设施设备应配置温湿度监测、记录、报警、调控装置,监控装置应定期校验并记录。设施设备应易于清洗、消毒、检查和维护。

3.2 冷库应具备配套的制冷系统或保温条件缓存区的封闭月台,同时与车辆对接处应有防撞密封设施。冷库门应配备限制冷热交换的装置,并设置防反锁装置和警示标识。

3.3 运输工具厢体应使用防水、防锈、耐腐蚀的材料,厢体内壁应保持清洁卫生、无毒、无害、无污染、无异味。应定期对运输工具的冷藏性能进行检查并记录。

3.4 应建立与储存、运输相配套的信息化系统,信息化系统应有储存、运输管理相应的模块。

3.5 需温湿度控制的食品在物流过程中应符合其标签标示或相关标准规定的温湿度要求。

3.6 当食品冷链物流关系到公共卫生事件时,应及时根据有关部门的要求,采取相应的预防和处置措施,对相关区域和物品按照有关要求进行清洗消毒,对频繁接触部位应适当增加消毒频次,防止与冷链物流相关的人员、环境和食品受到污染。

4 交接

4.1 交接环境应符合食品安全要求,并建立清洁卫生管理制度。

4.2 交接时应检查食品状态,并确认食品物流包装完整、清洁、无污染、无异味。

4.3 交接时应确认食品种类、数量、温度等信息,确认无误后尽快装卸,并做好交接记录。

4.4 交接时应测量食品外箱表面温度或内包装表面温度,并记录;如表面温度超出规定范围,还应测量食品中心温度。

4.5 交接时应严格控制作业环境温度并尽量缩短作业时间,以防止食品温度超出规定范围,如无封闭月台,装卸货间隙应随时关闭厢体门。

4.6 交接时应查验运输工具环境温度是否符合温控要求。入库和配送交接时,还应查验全程温度记录;出库交接时,还应查验在库温度记录。当温度或食品状态异常时,应不予接收。

4.7 当食品冷链物流关系到公共卫生事件时,应进行食品外包装及交接用相关用品用具的清洁和消毒。

5 运输配送

5.1 运输工具应保持清洁卫生,应建立清洁卫生消毒记录制度,定期对运输工具清洁、消毒。运输工具不得运输有毒有害物质,防止食品被污染。当食品冷链物流关系到公共卫生事件时,应增加对运输工具的厢体内外部、运输车辆驾驶室等的清洁消毒频次,并做好记录。

5.2 应根据食品的类型、特性、季节、运输距离等选择不同的运输工具和运输路线,同一运输工具运输不同食品及多点装卸时,应根据产品特性,做好分装、分离或分隔,并存放在符合食品储存温度要求的区域。

5.3 装货前应对运输工具进行检查,根据食品的运输温度对厢体进行预冷,并应在运输开始前达到食品运输需要的温度。

5.4 运输过程中的温度应实时连续监控,记录时间间隔不宜超过10min,且应真实准确。

5.5 当运输设备温度超出设定范围时,应立即采取纠正行动和应急措施,并如实记录超温的范围和时间。

5.6 运输过程中运输工具应采取安全性措施,如铅封或加锁等。运输过程宜保持平稳,装卸时应行动迅速、轻拿轻放,并尽量减少车厢开门次数和时间。

5.7 配送前应确认食品物流包装完整,温度符合要求。

5.8 需冷冻的食品在运输过程中温度不应高于-18℃;需冷藏的食品在运输过程中温度应在0℃-10℃。

6 储存

6.1 冷库的温度显示、区域划分标识应清晰规范,并做好温度记录,确保准确真实,记录间隔时间不超过30min。

6.2 冷库温度记录和显示设备宜放置在冷库外便于查看和控制的地方,温度传感器或温度记录仪应放置在最能反应食品温度或者平均温度的位置,建筑面积大于100㎡的冷库,温度传感器或温度记录仪数量不少于2个;应建立库房温度记录保存制度。

6.3 当冷库温湿度超出设定范围时,应立即采取纠正行动和应急措施,并如实记录超过的范围和时间。

6.4 不同品种、规格、批次的产品应分别堆垛,防止串味和交叉污染。储存的食品应与库房墙壁间距不少于10cm,与地面间距不少于10cm。

6.5 冷库机房应24h不间断运行并有应急措施。

6.6 冷库作业区应建立清洁卫生制度,并建立记录机制。当食品冷链物流关系到公共卫生事件时,应加强对货物转运存放区域、冷库机房的清洁消毒频次,并做好记录。

6.7 需冷冻的食品储存环境温度应不高于-18℃,需冷藏的食品储存环境温度应在0℃-10℃。对于有湿度要求的食品,还应满足相应的湿度储存要求。

7 人员和管理制度

7.1 应符合GB 31621的相关规定。

7.2 从事食品冷链物流各环节工作的人员,应接受运输、储存、配送、交接及突发状况应急处理等相关知识和技能培训,具备相应的能力,并有明确的职责和权限报告操作过程中出现的食品安全问题。

7.3 应建立食品运输、储存、配送、交接等环节温湿度及操作要求制度。

7.4 应建立有效的风险控制措施及应急预案。

7.5 当食品冷链物流关系到公共卫生事件时,应按照有关部门的要求,加强人员健康状况管理,根据岗位需要做好人员健康防护。

8 追溯及召回

8.1 应符合GB 31621的相关规定。

8.2 当食品冷链物流关系到公共卫生事件时,对受污染的食品,应按照有关部门的要求进行处置。

9 文件管理

9.1 应符合GB31621的相关规定。

9.2 文件保存期限不应少于食品保质期满后6个月;没有明确保质期的,保存期限应不少于2年。

9.3 当食品冷链物流关系到公共卫生事件时,应按照有关部门的要求执行。