由于持续的交通拥堵,圣诞节危机迫在眉睫

全球供应链问题正威胁着圣诞节向零售商发货,我们看到美国港口持续拥堵,现在英国部分地区也是如此。它继续扰乱世界各地的航运和货物运输。我们看到,宁波等中国主要集装箱港口的拥堵状况有所缓解,自8月中旬以来,等待的船舶数量减少了一半以上,但进口港口的拥堵状况令人担忧,因为港口难以清理集装箱吞吐量。

在过去的一年里,集装箱船市场承受着巨大的压力,因新冠肺炎而被压抑的需求推高了消费支出,中国的恶劣天气和因新冠肺炎而被封锁的码头导致港口高度拥堵。由于海上运输能力不足,航运费率继续收紧,而这些中断正在蔓延到陆上供应链。加州的进口港口长滩和洛杉矶是受影响最严重的港口之一,在圣诞节临近之际,严重的拥堵几乎没有缓解的迹象,因为停泊在港口等待卸货的船只数量达到了创纪录的水平。与一个月前相比,目前等待的船只数量增加了65艘左右。

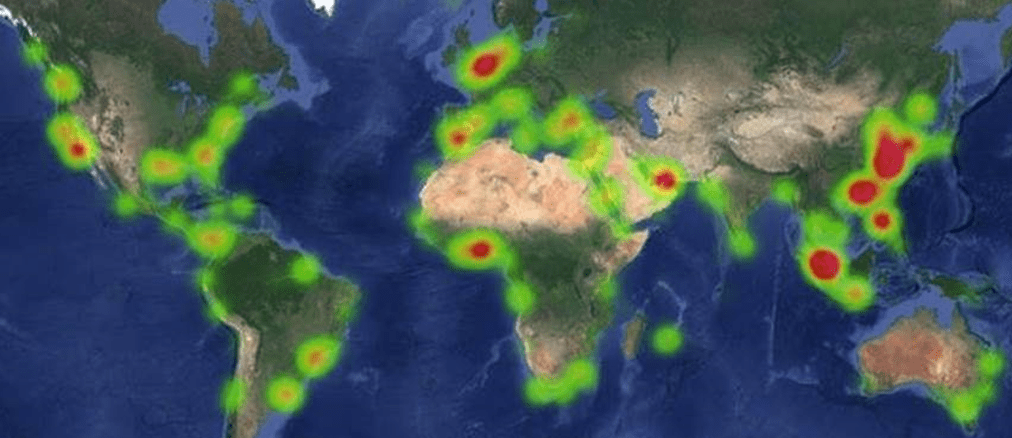

目前,全球有334艘集装箱船(ULCV - Sub Panamax)在港口外等待,总计超过220万TEU。

Felixstowe是英国主要集装箱港口之一,自2021年初以来,已接收927艘Post Panamax、554艘Panamax、532艘ULCV和484艘New Panamax集装箱船。大部分进入英国的集装箱是从中国出口枢纽运输制成品的,从玩具、健身器材、电器、服装到冷冻食品,英国40%的进口集装箱通过该港口。费利克斯托港是最新一个报告出现拥堵的港口,因为严重短缺的卡车司机意味着集装箱在港口堆场堆积起来。这使得卸货和将空集装箱重新装回亚洲港口变得越来越困难。

由于港口堆积的集装箱,船只在港口卸货和启航的时间比平时长,导致班轮时刻表中断,进一步减少了船只的可用性。自本月初以来,已有31艘船只通过费利克斯托港,相当于281,408个TEU船舶的总容量。这比2020年同期减少了45%,比2019年同期减少了51%,表明该港口在周转时间上遇到了困难。

由于这个主要港口没有稳定的集装箱流动,也没有足够的卡车来重新分配制成品,由此所看到的供应中断可能意味着零售商在这个圣诞节期间很难填满货架。一些航运公司报告称,他们正将船只转向其他欧洲港口,以避开费利克斯托的瓶颈,保持船只畅通。这艘18340teu的Marchen Maersk号于10月13日从Tanger Med出发,从Felixstowe转向德国Wilhelmshaven,以加快卸货速度。

耗时越长,成本越高,因此,对于航运公司来说,被迫做出改变航线的决定,以及在拥挤的港口受阻,成本都很高。在一年的这个时候,零售商的销售额也占了最大的比例,所以如果零售商难以获得足够的库存,利润率下降,我们可能会看到价格回落到消费者手中。

我们还可能看到,在商店中购买产品的替代运输方式的使用在增加,如铁路和航空货运,尽管配送问题同时影响了供应链的大部分部分。